Description:

Our Rotary Dryers are custom engineered to reach optimum drying efficiency.

DEVICE DETAILS

We’ve built a reputation on building the best rotary dryers in the industry. All of our dryers are custom designed to suit the unique processing needs of your material. Whether you require low or high inlet temperatures, short or long residence times, counter current or co-current flow, EMCC’s design team can design a rotary drum dryer for your application.

Rotary dryers are a highly efficient industrial drying option for bulk solids. They are often chosen for their robust processing capabilities and their ability to produce uniform results despite variance in feedstock.

Rotary dryers work by tumbling material in a rotating drum in the presence of a drying air. They can also be indirectly heated to avoid direct contact between the material and processing medium.

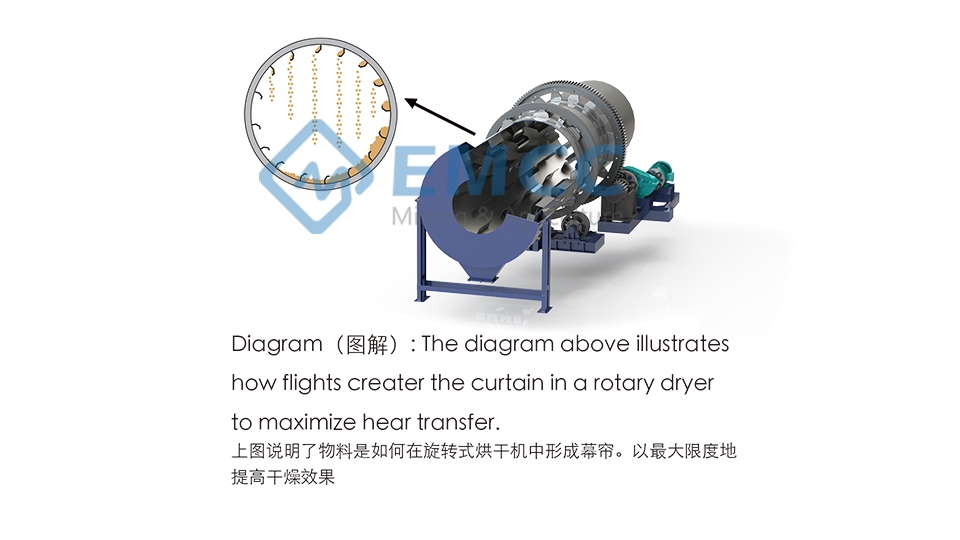

The drum is positioned at a slight horizontal slope to allow gravity to assist in moving material through the drum. As the drum rotates, lifting flights pick up the material and drop it through the air

stream in order to maximize heat transfer efficiency. When working with agglomerates, the tumbling action imparted by the dryer offers the added benefit of further rounding and polishing the granules.

| -Optional Components | -Knocking Systems | -Trommel Screen | -Liners |

| -Leaf Seals | -Graphite Seals | -Machined Bases | -Screw Conveyor Feeder |

| -Automatic Gear Lubrication System | -Exhaust Handling Equipment | -Ductwork | -Material Options |

| -Carbon Steel | -Stainless Steel | -Specialty Alloys | -Explosion Bonded |

| -AR Steel | -Accommodates Various Fuel Types | -Fuel Oil | -Natural Gas/Propane |

| -Waste Heat | -Biogas |

APPLICATIONS & MATERIALS

Rotary dryers are known as the workhorse of industrial dryers. They are able to process a wide variety of materials, and can lenda hand in nearly any industry requiring industrial drying solutions.

Some of the most common industries and materials in which rotary dryers are employed include:

| -Aggregates | -Agricultural By | -Products | -Animal Feeds |

| -Biomass | -Biosolids | -Fertilizers | -Fly Ash |

| -Gypsum | -Inorganic Chemicals | -Limestone | -Manure |

| -Metal Chips & Shavings | -Mining Ores & Concentrates | -Municipal Waste & Sludge | -Organic Chemicals |

| -Paper Sludge | -Plastic Pellets & Grains | -Potash | -Reclaimed Dust |

TECHNICAL PARAMETERS

| Model | Drum diameter (mm) | Drum length(mm) | Inlet temp of hot air(℃) | Capacity (t/h) | Power (kw) |

| HG0606 | 600 | 6000 | ≤700 | 0.5-1.5 | 3 |

| HG0808 | 800 | 8000 | ≤700 | 0.8-2.0 | 4 |

| HG0810 | 800 | 10000 | ≤700 | 0.8-2.5 | 4 |

| HG1010 | 1000 | 10000 | ≤700 | 1.0-3.5 | 5.5 |

| HG1210 | 1200 | 10000 | ≤700 | 1.8-5 | 7.5 |

| HG1212 | 1200 | 12000 | ≤700 | 2-6 | 11 |

| HG1512 | 1500 | 12000 | ≤800 | 3.5-9 | 15 |

| HG1812 | 1800 | 12000 | ≤800 | 5-12 | 18 |

| HG2212 | 2200 | 12000 | ≤800 | 6-15 | 18.5 |

| HG2218 | 2200 | 18000 | ≤800 | 10-18 | 22 |

| HG2220 | 2200 | 20000 | ≤800 | 12-20 | 30 |

| HG2420 | 2400 | 20000 | ≤800 | 18-30 | 37 |

| HG3020 | 3000 | 20000 | ≤800 | 25-35 | 55 |

| HG3025 | 3000 | 25000 | ≤800 | 32-40 | 75 |

ADVANTAGE

FEATURES

Diameter: 1m – 4.6m

Capacity: 1 TPH – 200 TPH (1 MTPH – 181 MTPH+)

Specially designed lifting flights to maximize heat transfer between the material and hot gas stream

Heavy duty design and construction for many years of service

Process and Mechanical Warranties

WORKING PRINCIPLE

Rotary drum dryer adopts slightly tilted drum which can be rotated. The wet materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator from the higher side, and well-dried materials are collected from the other lower side, and hot air enters the drum from the feeding side or discharging side according to user needs.