Description:

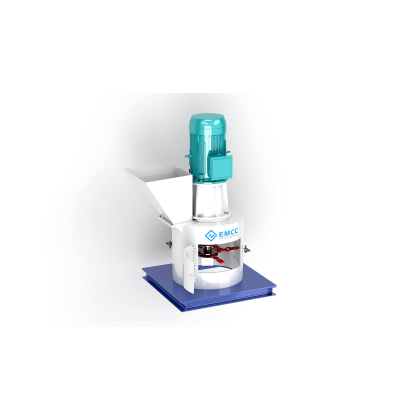

Vertical chain crusher is specially designed to crush large fertilizer particles and returning fertilizers with less than 6% moisture content in compost production.Hard fertilizer particles like ammonium and carbamide are also a piece of cake to vertical chain crusher.

DEVICE DETAILS

Vertical chain crusher is specially designed to crush large fertilizer particles and returning fertilizers with less than 6% moisture content in compost production.Hard fertilizer particles like ammonium and carbamide are also a piece of cake to vertical chain crusher. Its crushing role also covers industries like compost fertilizer,bio-organic fertilizer,chemical and feed,etc. The rational chain design and robust composing materials highlight our vertical chain crusher, so for various sizes fertilizer plants, it is certainly your first choice.

TECHNICAL PARAMETERS

| Model | Capacity(t/h) | Power(kw) | Inlet size(mm) | Dimension(mm) |

| LF-600 | 3-5 | 15 | 400×400 | 2100x1200x1700 |

| LF-800 | 5-8 | 30 | 600×400 | 2600x1400x1900 |

| LF-1000 | 8-15 | 37 | 650×450 | 2800x1600x1000 |

ADVANTAGE

1. It is vertical chain crusher for middle size

2. Crushing materials uniformly, smooth operation

3. Not easy to stick on the wall and easy to clean

4. It’s the enemy of large lump materials

5. Rational structure with removable back plate, convenient maintenance

6. Small room occupation, high volume

WORKING PRINCIPLE

The motor drives chain plates rotating and due to the centrifugal force, the chains whip fast and form two turning surfaces. When the fertilizer slump from feeding inlet, it is cracked down by the upper chain and become smaller particles, at the same time, it is thrown onto the inner liner and drop to the lower chain plates. Then the lower chain also impacts smaller particles and strike it to smash. That means the fertilizer materials crushing process is such a model like struck-crushed-thrown-struck-smashed.